Indeed, the area near the end of the fibre where the transmitter is located reflects the first received echo, then the one emitted immediately after, and so on, until the echo emitted by the other end of the fiber.

In practice, with the best industrial optoelectronic interrogators currently available on the market, accuracies of 0.1°C per meter every 10 minutes, and 2×10⁻⁶ per meter every 10 minutes

–

that is, 2 µm over 1 meter along the length of the fiber (within the limits of deformations greater than 10⁻², which break the fibers)

–

can be achieved every 10 minutes. By combining these measurements with high-frequency acquisitions, the fibre can be transformed into an acoustic sensor.

The fibers of these

« fibre optics monitoring systems »

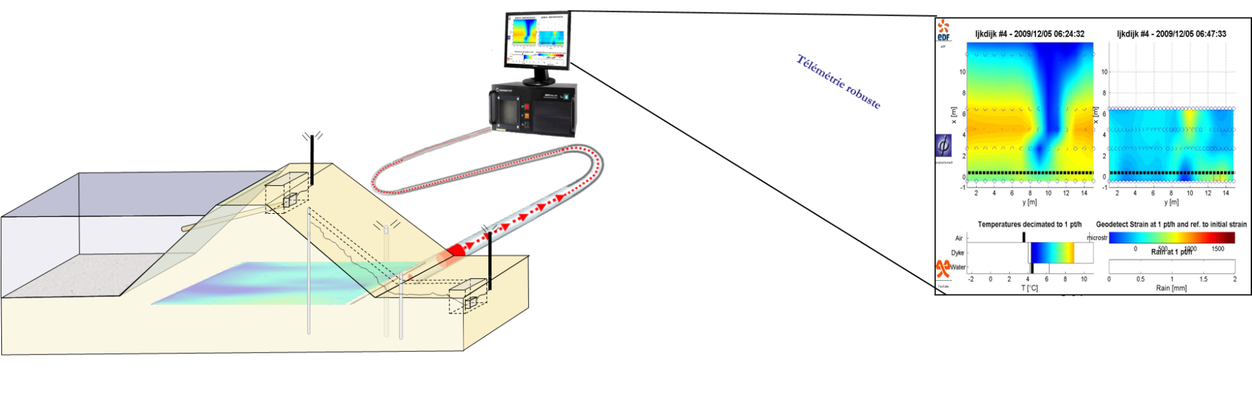

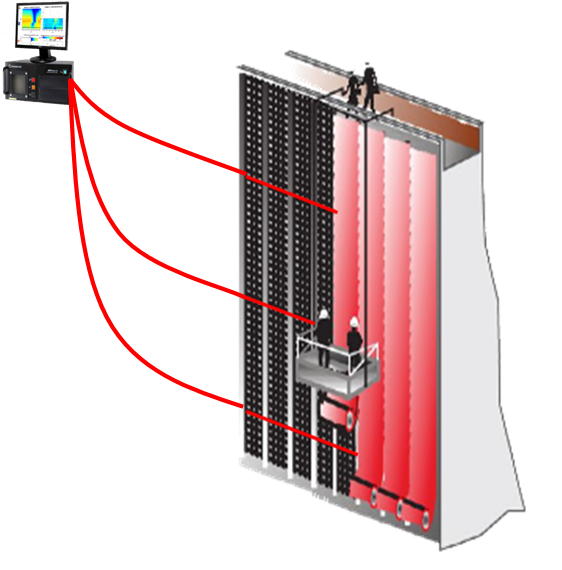

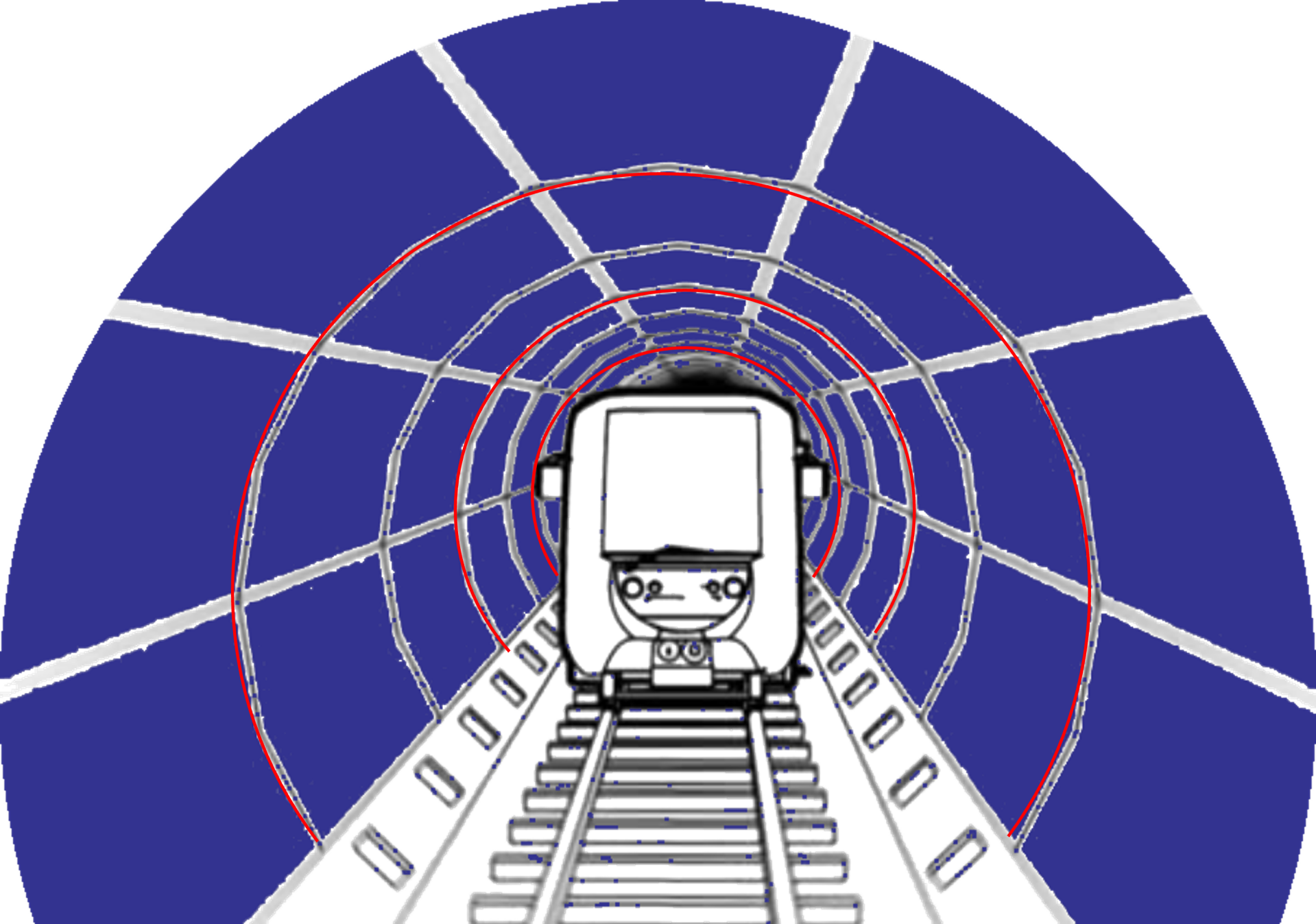

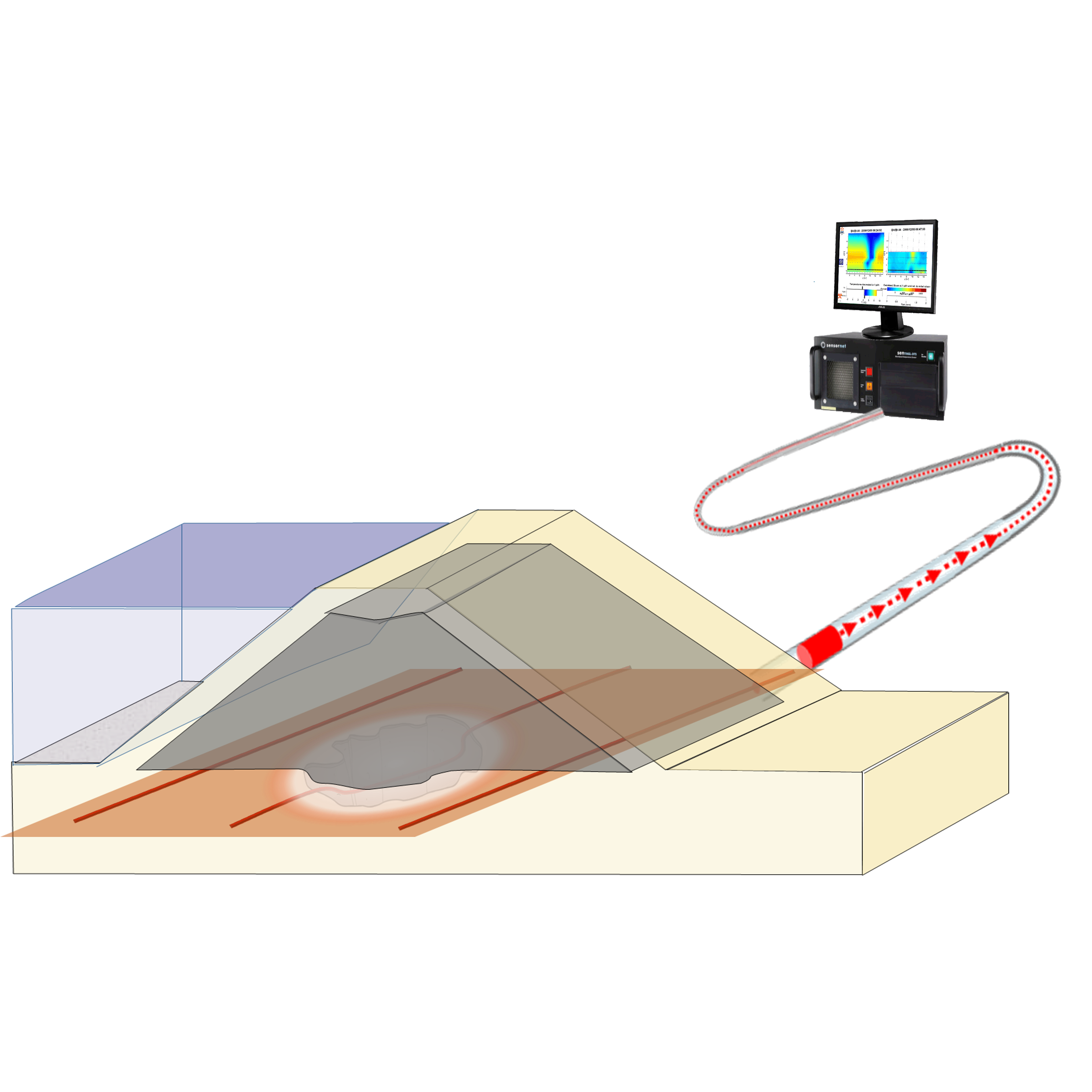

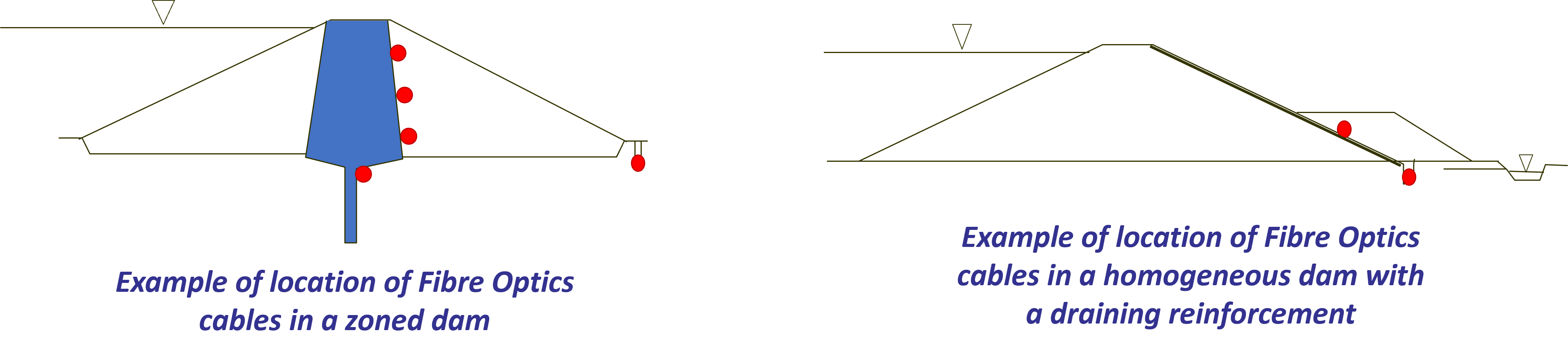

can be buried in structures or bonded to their surface. They can therefore be used, for example, to measure temperature, deformation and acoustic or seismic noise present on virtually any type of structure (dikes, dams, tunnels, bridges, roads, pipelines, high-voltage pylons, buildings, etc.).